The Real Costs of Engine Block Repair

I. Introduction

- Briefly introduce the topic of engine block repair and replacement.

- Highlight the importance of making informed economic decisions in the automotive industry.

- Present the key questions the blog post aims to answer.

II. Understanding Engine Block Repair and Replacement

- Explain what an engine block is and its significance in a vehicle.

- Provide an overview of common issues that may necessitate repair or replacement.

- Discuss the two main options: rebuilding the engine block and opting for a new one.

III. The Costs of Rebuilding an Engine Block

- Break down the costs involved in rebuilding an engine block.

- Include components like labor, parts, and any additional expenses.

- Share examples and case studies to illustrate potential costs.

IV. The Costs of Replacing an Engine Block

- Discuss the expenses associated with replacing the engine block.

- Mention factors that influence the cost, such as the type of engine and vehicle.

- Use real-world examples to demonstrate the cost differences.

V. Long-Term Savings: Rebuilding vs. Replacing

- Analyze the long-term cost savings of rebuilding an engine block.

- Explain how a well-rebuilt engine can extend the life of a vehicle.

- Explore potential maintenance costs over time in comparison to replacement.

VI. Return on Investment (ROI) Considerations

- Introduce the concept of ROI and its importance in this context.

- Evaluate the ROI of rebuilding an engine block, emphasizing the payback period.

- Discuss the ROI implications of opting for a new engine block.

VII. Factors Influencing the Decision

- Highlight key factors that can impact the decision between rebuilding and replacing.

- Include considerations like the age of the vehicle, personal attachment, and intended use.

- Present a decision-making framework to help readers assess their unique situation.

VIII. Real-Life Success Stories

- Share success stories from individuals or businesses that made wise engine block decisions.

- Highlight how their choices led to financial benefits and improved vehicle performance.

IX. Conclusion

- Summarize the key points of this blog post.

- Reiterate the importance of informed decision-making in the automotive industry.

- Encourage readers to carefully evaluate their circumstances when faced with engine block issues.

This outline provides a structured framework for your blog post on the economic considerations of rebuilding vs. replacing an engine block, along with thought-provoking questions to engage your readers.

I. Introduction

When it comes to automotive maintenance, one of the most critical decisions a vehicle owner can face is whether to rebuild the engine block or opt for a new one. This choice carries significant financial implications, affecting not only the immediate budget but also long-term savings and return on investment (ROI). In this blog post, we will delve into the financial aspects of this decision, breaking down the costs, exploring long-term savings, and evaluating the ROI to help you make an informed choice.

II. Understanding Engine Block Repair and Replacement

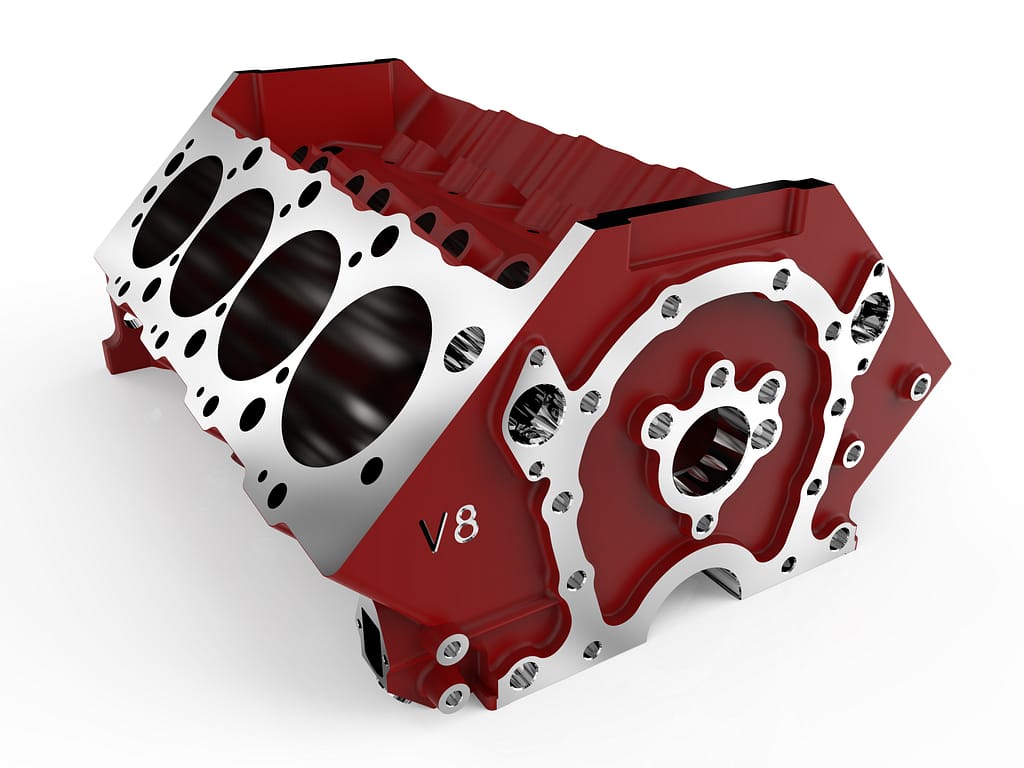

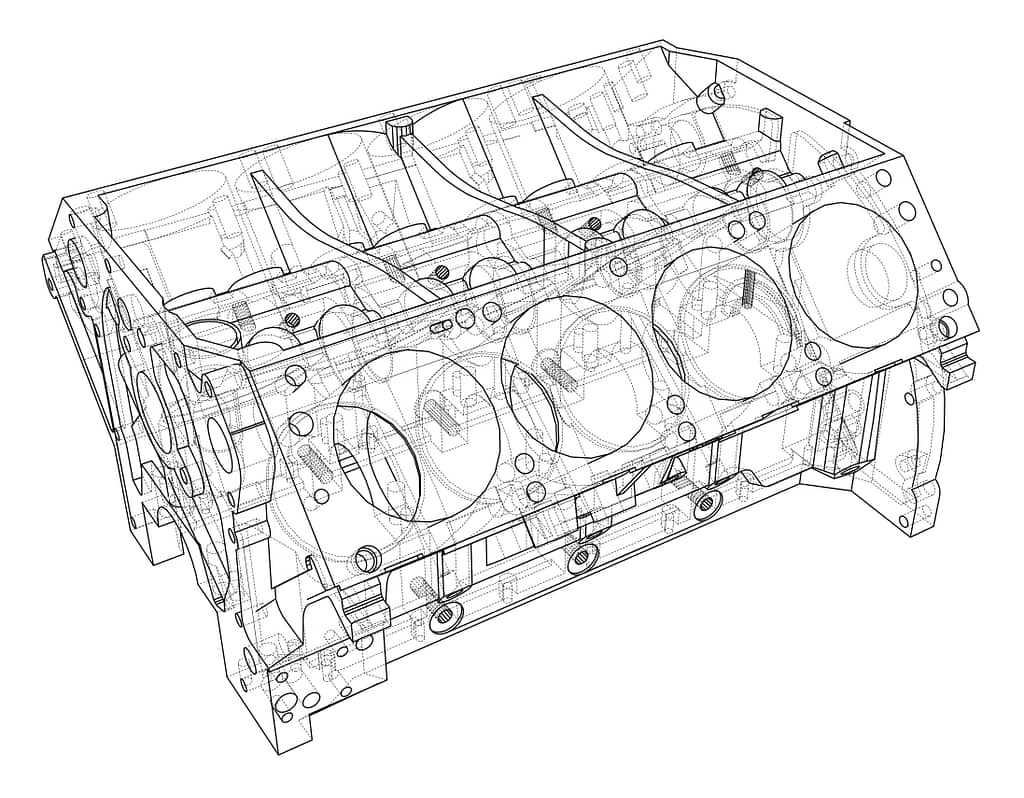

Before we dive into the financial considerations, let’s start by understanding what an engine block is and why it’s essential for your vehicle. The engine block, also known as the cylinder block, is the core component of your engine. It houses the cylinders, pistons, and various critical components that power your vehicle. When the engine block develops issues, you are faced with a choice: rebuild or replace it.

A. What is an Engine Block?

The engine block is the foundation of your vehicle’s engine. It provides structural support and contains several key components, including the cylinders, crankshaft, and camshaft. A functioning engine block is crucial for your vehicle’s performance and reliability.

B. Common Issues Necessitating Repair or Replacement

Engine blocks can develop various issues over time, leading to a decision point for vehicle owners. Some common problems include:

- Cracks: Cracks in the engine block can result from overheating or stress. These cracks can cause coolant leaks, leading to engine overheating and potentially catastrophic damage.

- Cylinder Wear: Over time, the cylinders in the engine block can wear out, resulting in reduced engine performance and efficiency.

- Warped Block: A warped engine block can cause head gasket leaks, leading to coolant and oil mixing. This can damage critical engine components and lead to poor performance.

- Corrosion: Corrosion can eat away at the engine block, weakening its structure and potentially causing leaks.

- Piston Damage: Damage to the pistons, which move within the cylinders of the engine block, can necessitate repairs or replacement.

Each of these issues presents a unique set of challenges and potential costs, deciding between rebuilding and replacing a complex one.

III. The Costs of Rebuilding an Engine Block

Rebuilding an engine block involves disassembling the engine, assessing the extent of damage, and replacing or repairing components as needed. Let’s break down the costs involved in this process.

A. Cost Components

- Labor: The labor cost can be a significant portion of the total expense. Skilled mechanics or engine specialists need to disassemble the engine, diagnose the issues, and perform the necessary repairs.

- Parts: Replacement parts vary depending on the extent of the damage. This can include gaskets, seals, pistons, bearings, and other components.

- Machine Work: Engine block repair often requires machine work to smooth out any imperfections or damage. This cost includes services such as cylinder boring or honing.

- Additional Expenses: These can include gasket kits, engine machining, and any unexpected issues discovered during the repair process.

B. Real-World Examples

To illustrate the potential costs of rebuilding an engine block, let’s consider a few real-world examples:

Example 1: A Cracked Engine Block

Imagine you have a vehicle with a cracked engine block due to overheating. After a thorough inspection, the mechanic recommends a rebuild. Here’s a rough breakdown of the costs:

- Labor: $1000 – $2,000

- Parts: $700 – $1,700

- Machine Work: $500 – $700

- Additional Expenses: $300 – $800

In this scenario, the total cost to rebuild the engine block could range from $1,600 to $3,700, depending on the specific issues and the quality of parts and labor.

Example 2: Cylinder Wear

Suppose you’re driving a high-mileage vehicle with worn-out cylinders, causing reduced engine power and efficiency. A rebuild may be necessary. Here’s a potential cost breakdown:

- Labor: $1000 – $1,500

- Parts: $800 – $1,200

- Machine Work: $300 – $700

- Additional Expenses: $200 – $300

In this case, the total cost of rebuilding the engine block might vary from $1,800 to $2,900, depending on factors such as your location and the mechanic’s rates.

These examples emphasize that the cost of rebuilding an engine block can vary significantly based on the vehicle, the extent of damage, and the local market. It’s essential to obtain estimates from qualified mechanics to get a precise idea of what you might expect to pay.

IV. The Costs of Replacing an Engine Block

Replacing an engine block involves installing a brand-new or refurbished block as a direct swap for the old one. Let’s discuss the expenses associated with this approach.

A. Factors Influencing the Cost

The cost of replacing an engine block can be influenced by several factors:

- Type of Engine: The specific engine in your vehicle, including its make and model, can affect the cost. Some engines are more readily available and affordable than others.

- Vehicle Make and Model: Different vehicles have varying degrees of complexity when it comes to replacing the engine block. High-performance or luxury vehicles may require more specialized parts, which can be expensive.

- New vs. Remanufactured Blocks: You can choose between a brand-new engine block or a remanufactured one. Remanufactured blocks are often more cost-effective but can be as reliable as new ones.

- Labor Costs: Labor costs for engine replacement can also vary depending on the complexity of the job and your location.

B. Real-World Examples

To provide a sense of the potential costs of replacing an engine block, let’s consider a couple of scenarios:

Example 1: A Common Vehicle Model

Suppose you have a popular, everyday vehicle with a relatively common engine. In this case, you might find a suitable replacement engine block for a cost that ranges from $1,500 to $3,000, depending on factors like whether you choose a new or remanufactured block.

Labor costs for installation could range from $1,700 to $3,250, depending on your location and the complexity of the job. Therefore, the total cost of replacing the engine block in this scenario could be between $3,200 and $6,250.

Example 2: A Specialized Vehicle

Now, consider a high-performance or luxury vehicle with a more complex engine. Replacement engine blocks for such vehicles can be significantly more expensive, ranging from $3,000 to $6,000 or more for the block alone.

Labor costs for these types of vehicles can also be higher due to the additional expertise and time required. Labor costs may range from $2,000 to $4,000 or more, depending on location and vehicle complexity. Therefore, the total cost of replacing the engine block in this scenario could be between $5,000 and $10,000 or even higher.

These examples highlight that the cost of replacing an engine block can fluctuate widely, depending on the specific vehicle, engine type, and local factors. It’s essential to obtain quotes from mechanics or engine suppliers to determine the precise costs for your situation.

V. Long-Term Savings: Rebuilding vs. Replacing

Beyond the initial costs, it’s essential to consider the long-term savings associated with rebuilding and replacing an engine block. These savings can significantly influence your decision, as they impact the total cost of ownership over the life of your vehicle.

A. Rebuilding for Long-Term Savings

Rebuilding an engine block can lead to long-term savings in several ways:

- Extended Engine Life: A well-rebuilt engine block can extend the life of your vehicle, potentially adding several years of reliable service. This longevity can save you from having to purchase a new vehicle sooner.

- Reduced Maintenance Costs: A properly rebuilt engine block is less likely to develop issues in the future, reducing the need for costly repairs. This can lead to lower maintenance expenses over time.

- Enhanced Fuel Efficiency: Rebuilding an engine block can often result in improved fuel efficiency, saving you money at the pump throughout the vehicle’s extended life.

- Preserving the Vehicle’s Value: If you have a vehicle with sentimental or collector value, rebuilding the engine block can help maintain or even increase its worth over time.

- Environmentally Friendly: Choosing to rebuild rather than replace can be more environmentally responsible, as it reduces the demand for new engine blocks and the disposal of old ones.

B. Replacing for Long-Term Savings

Replacing an engine block can also offer long-term savings, albeit in a different way:

- Warranty: New or remanufactured engine blocks often come with warranties. These warranties can provide peace of mind and protection against unexpected issues, potentially saving you money on future repairs.

- Predictable Performance: A replacement engine block, especially if it’s new or remanufactured, can provide predictable and reliable performance, reducing the risk of unexpected breakdowns and associated expenses.

- Resale Value: In some cases, replacing the engine block can improve the resale value of your vehicle, especially if it’s a high-quality, factory-remanufactured block.

- Reduced Maintenance: With a new or remanufactured engine block, you’re likely to experience fewer maintenance issues in the near term, reducing the need for costly repairs.

It’s important to note that the long-term savings of rebuilding vs. replacing can vary depending on factors such as the quality of the work performed, the reliability of replacement engine blocks, and how well the vehicle is maintained over time. Therefore, your choice should align with your specific circumstances and goals.

VI. Return on Investment (ROI) Considerations

Now that we’ve explored the costs and potential long-term savings of rebuilding and replacing an engine block, let’s introduce the concept of Return on Investment (ROI). ROI is a crucial financial metric that can help you assess the financial impact of your decision.

A. The Role of ROI

ROI is a metric that evaluates the financial returns generated by an investment in comparison to the initial cost of that investment. In the context of engine block repair or replacement, ROI helps you assess whether the money spent will yield returns in the form of cost savings, improved performance, or increased vehicle value.

B. Evaluating the ROI of Rebuilding an Engine Block

To calculate the ROI of rebuilding an engine block, you need to consider the initial cost of the repair and the expected financial benefits over time. Here’s a basic formula to calculate ROI:

ROI = (Net Gain / Cost of Rebuilding) x 100

- Net Gain: This is the total financial benefit you expect to receive from the rebuild. It includes savings on maintenance and repair costs, extended vehicle life, and improved fuel efficiency.

- Cost of Rebuilding: This is the total cost of rebuilding the engine block, including labor, parts, machine work, and additional expenses.

Once you’ve calculated ROI, you can assess whether the investment in rebuilding the engine block is financially sound. If the ROI is positive, it suggests that the financial benefits outweigh the initial cost.

C. Discussing the ROI Implications of Opting for a New Engine Block

Similar to calculating ROI for rebuilding, you can also evaluate the ROI of opting for a new engine block. Here, you’ll consider the initial cost of replacement and the expected financial benefits.

ROI = (Net Gain / Cost of Replacement) x 100

- Net Gain: This includes savings on maintenance, warranty benefits, and potential resale value improvements.

- Cost of Replacement: This is the total cost of replacing the engine block, including the block itself, labor, and related expenses.

By comparing the ROI of rebuilding to the ROI of replacing, you can make a more informed decision based on your specific financial goals and priorities.

VII. Factors Influencing the Decision

The decision to rebuild or replace an engine block is not solely about costs and ROI. Several other factors should influence your choice, as they can significantly impact your experience as a vehicle owner.

A. Age of the Vehicle

The age of your vehicle plays a crucial role in your decision. For a relatively new vehicle with a damaged engine block, the financial benefits of rebuilding may outweigh the cost of replacement. However, for an older vehicle with multiple issues, it might be wiser to consider replacement, as other components are likely to need attention soon.

B. Personal Attachment

Your emotional connection to your vehicle can also influence your decision. If you have a classic car, a vehicle with sentimental value, or one that has been customized to your preferences, you might lean towards rebuilding the engine block, preserving the unique characteristics of your vehicle.

C. Intended Use

Consider how you intend to use your vehicle after the repair or replacement. If you’re planning to keep it for an extended period and rely on it for daily transportation, long-term savings, and reliability become paramount. On the other hand, if you’re thinking of selling the vehicle soon, the financial benefits of replacement and a warranty might be more appealing.

D. Mechanics’ Expertise

The skill and expertise of the mechanics available to you are critical. Rebuilding an engine block requires precision and knowledge. If you have access to experienced mechanics who specialize in engine work, rebuilding may be a more attractive and cost-effective option.

VIII. Real-Life Success Stories

To better understand the financial implications of rebuilding vs. replacing an engine block, let’s look at some real-life success stories from vehicle owners and businesses. These stories highlight the decisions made, the outcomes, and how those choices influenced their finances and overall satisfaction with their vehicles.

A. The Classic Car Enthusiast

John, a classic car enthusiast, owned a vintage sports car that he had painstakingly restored over the years. The engine block developed issues, and he faced a difficult decision. John decided to rebuild the engine block, even though it was a significant investment.

The Result:

- The rebuild was successful, and John’s car retained its original engine.

- The vehicle’s value increased due to the preservation of its original components.

- John’s emotional connection to his car remained strong, and he continued to enjoy driving it for years to come.

B. The Fleet Manager

Sarah managed a small fleet of delivery vans for her business. One of the vans had an aging engine block that was causing frequent breakdowns and increasing maintenance costs. She decided to replace the engine block with remanufactured ones for several vans in her fleet.

The Result:

- The replacement significantly reduced the frequency of breakdowns, improving the vans’ reliability.

- Sarah’s maintenance costs dropped, leading to substantial annual savings.

- The business’s reputation for on-time deliveries and service reliability improved, attracting more clients and revenue.

These stories show that the decision to rebuild or replace an engine block can vary greatly based on individual circumstances. John’s decision was driven by his attachment to a classic car, while Sarah’s decision was made with a focus on business efficiency and cost savings.

IX. Conclusion

In the world of automotive maintenance, the choice between rebuilding and replacing an engine block is not one to be taken lightly. It’s a decision with far-reaching financial implications, affecting your immediate budget, long-term savings, and return on investment.

As we’ve explored, the decision is complex, involving factors like the specific issues with the engine block, the costs involved, long-term savings, and ROI. Additionally, personal attachment to your vehicle and your intended use plays a significant role.

Ultimately, the right choice for you will depend on your unique situation and priorities. By carefully assessing the factors discussed in this blog post, seeking expert advice, and considering real-life success stories, you can make an informed decision that best aligns with your goals and finances.

In the end, whether you choose to rebuild or replace, the key is to ensure the work is carried out by skilled professionals who can deliver a reliable, cost-effective solution. Your vehicle’s engine is its heart, and your decision should lead to many more miles of happy and trouble-free driving.

Check out How To Install An Engine In Your Car

We have several Tips articles and videos on the subject of providing useful tips and tricks to address common problems to fix, and upgrades to improve your vehicle’s performance, reliability, and longevity.

Tips For Upgrading Your Vehicle

- What Are The Most Important Upgrades You Can Do To Your Car?

- Install a performance exhaust system

- Upgrade Your Air Filter

- Cold Air Intake System

- Spark plugs and wires

- Fuel System

- Change Your Oil Regularly

- Performance Chip

- Performance Tires

- Performance Camshaft

- Aftermarket Cylinder Heads

- Replace Your Brake Pads and Rotors

- Power Adders (Turbocharger or Supercharger)

- Nitrous Oxide System

- Rebuild or Replace your Engine

Here is a post I made a while ago, Where Can I Find Crate Engines? And here is this article, Check Our Availability On Engine Blocks And Crate Engines.