Engine Technology’s Influence on Rebuilding vs. Replacing Engine Blocks

Introduction

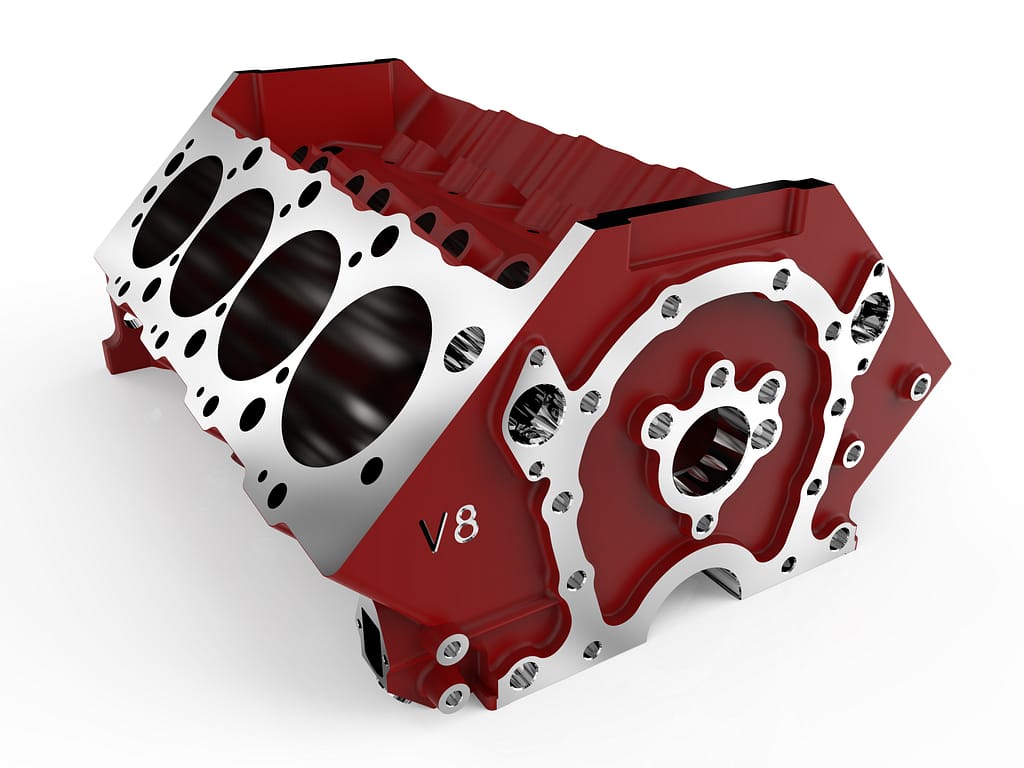

As engine builders, we find ourselves at a critical juncture in the world of automotive engineering. The decision to rebuild or replace an engine block has always been at the heart of our craft. However, in today’s rapidly evolving landscape of engine technology, this decision is more complex than ever before. In this in-depth exploration, we will dissect the impact of advances in engine technology on our decision-making process. From materials science to performance enhancements, we’ll delve into the factors that influence our choices, providing a comprehensive guide for engine builders facing the crossroads of tradition and innovation.

Article Outline

I. The Evolution of Engine Technology

A. Historical Perspective on Engine Rebuilding

B. The Role of Engine Technology in Modern Vehicles

C. Key Technological Advancements in Engine Design

II. Engine Rebuilding: An Art and a Science

A. The Process of Engine Rebuilding

1. Inspection and Assessment

2. Disassembly and Cleaning

3. Machining and Resurfacing

4. Component Selection and Assembly

5. Testing and Quality Assurance

B. Advantages of Engine Rebuilding

1. Cost-Effectiveness

2. Preservation of Originality

3. Customization Opportunities

III. Engine Replacement: A Modern Approach

A. Introduction to Engine Replacement

B. Types of Replacement Engines

1. Remanufactured Engines

2. New Engines

3. Performance and Aftermarket Options

C. Advantages of Engine Replacement

1. Time and Labor Savings

2. Warranty and Reliability

3. Compatibility with Modern Technologies

IV. The Role of Advanced Materials

A. Lightweight Materials in Engine Blocks

B. High-Strength Alloys and Their Impact

C. Benefits of Advanced Materials in Rebuilding vs. Replacement

V. Performance Enhancements Through Technology

A. Direct Injection and Its Impact

B. Turbocharging and Supercharging

C. Variable Valve Timing (VVT) and Efficiency Gains

VI. Electronics and Engine Management

A. Engine Control Units (ECUs)

B. Tuning and Calibration

C. Diagnostics and Troubleshooting

VII. Environmental Considerations

A. Emissions Compliance and Regulations

B. Eco-Friendly Options: Electric and Hybrid Engines

VIII. Decision-Making Factors for Engine Builders

A. Cost Analysis: Rebuilding vs. Replacement

B. Vehicle Application and Intended Use

C. Customer Preferences and Budget

D. Long-Term Reliability and Warranty

IX. Case Studies: Real-World Scenarios

A. Case Study 1: Restoring a Vintage Muscle Car

B. Case Study 2: Fleet Maintenance and Cost Savings

C. Case Study 3: High-Performance Engine Upgrades

X. Future Trends in Engine Technology

A. Predictions and Innovations

B. The Intersection of AI and Engine Building

C. Sustainable Engine Technologies

XI. Conclusion: Navigating the Crossroads

I. The Evolution of Engine Technology

Historical Perspective on Engine Rebuilding

Engine rebuilding has long been a cornerstone of automotive maintenance, dating back to the early days of the automobile. When vehicles were simpler, less sophisticated machines, rebuilding was often the most viable option to extend an engine’s life. Engine builders of the past relied on their craftsmanship, basic tools, and a deep understanding of mechanical principles to breathe new life into worn-out engines.

The Role of Engine Technology in Modern Vehicles

Today, the automotive landscape has transformed dramatically. Modern vehicles are equipped with highly sophisticated engines that incorporate cutting-edge technology to enhance performance, fuel efficiency, and environmental friendliness. Advances in engine technology have changed not only the way engines are built but also the options available when an engine needs attention.

Key Technological Advancements in Engine Design

The journey of engine technology evolution has been marked by significant milestones:

- Fuel Injection Revolution: The transition from carbureted systems to electronic fuel injection brought precise control of air-fuel mixture ratios, resulting in improved fuel efficiency and reduced emissions.

- Computer-Aided Design (CAD): CAD software has revolutionized engine design, enabling engineers to optimize components for efficiency and performance.

- Materials Science: Advances in materials science have led to the use of lightweight alloys, high-strength steels, and composite materials in engine construction.

II. Engine Rebuilding: An Art and a Science

The Process of Engine Rebuilding

Engine rebuilding is a meticulous process, comprising several essential steps:

- Inspection and Assessment: The first step involves a thorough examination of the engine to identify damaged or worn-out components. Engine builders must possess a keen eye for detail to pinpoint issues that may not be immediately apparent.

- Disassembly and Cleaning: Once the assessment is complete, the engine is carefully disassembled, and all components are removed. The components are then meticulously cleaned and inspected for further damage.

- Machining and Resurfacing: Engine blocks are often machined to restore their original specifications. Cylinder heads may require resurfacing to ensure a proper seal when reassembled.

- Component Selection and Assembly: Choosing the right components is crucial. Engine builders must decide whether to use new, refurbished, or custom-made parts. Assembling the engine with precision and attention to detail is a critical phase.

- Testing and Quality Assurance: Rigorous testing is the final step in ensuring a rebuilt engine’s reliability. Engines are tested for performance, compression, and any potential issues before being declared fit for use.

Advantages of Engine Rebuilding

Engine rebuilding remains a compelling choice for several reasons:

- Cost-Effectiveness: Rebuilding an engine is often more budget-friendly than replacing the entire engine block. It allows vehicle owners to save money while extending the life of their vehicle.

- Preservation of Originality: For classic car enthusiasts and collectors, preserving the original engine is paramount. Rebuilding allows for the retention of historical and intrinsic value.

- Customization Opportunities: Engine builders can tailor the rebuilt engine to meet specific performance goals. This flexibility is particularly appealing for those seeking unique and specialized outcomes.

III. Engine Replacement: A Modern Approach

Introduction to Engine Replacement

In contrast to traditional rebuilding, engine replacement offers a modern and convenient approach to addressing engine issues. It involves removing the existing engine block and replacing it with a different one, either remanufactured or brand new.

Types of Replacement Engines

There are several options available when considering engine replacement:

- Remanufactured Engines: Remanufactured engines are essentially rebuilt engines that have undergone a thorough overhaul to meet or exceed original equipment manufacturer (OEM) specifications. They typically come with warranties and offer a balance between cost savings and performance reliability.

- New Engines: Installing a brand-new engine block provides unparalleled reliability and longevity. New engines often come with warranties that can provide peace of mind to vehicle owners.

- Performance and Aftermarket Options: For enthusiasts seeking increased power and performance, aftermarket engines designed for specific applications are available. These engines are typically engineered for performance and can be a tempting choice for builders looking for maximum power output.

Advantages of Engine Replacement

Engine replacement presents several advantages:

- Time and Labor Savings: Swapping out an old engine for a remanufactured or new one can significantly reduce labor costs and downtime. This is particularly attractive for fleet maintenance and daily drivers.

- Warranty and Reliability: Replacement engines often come with warranties, providing a sense of security regarding future performance and maintenance costs.

- Compatibility with Modern Technologies: Replacement engines, especially remanufactured or new units, are often designed to comply with modern emissions standards and incorporate the latest technological advancements. This ensures compatibility with advanced features and emission control systems.

IV. The Role of Advanced Materials

Lightweight Materials in Engine Blocks

Advances in materials science have ushered in a new era of engine construction. Lightweight materials, such as aluminum and composite alloys, have become increasingly prevalent in engine block design. These materials offer advantages in weight reduction, improving fuel efficiency and vehicle handling.

High-Strength Alloys and Their Impact

High-strength alloys, including advanced steels and titanium, enhance engine block durability and performance. These alloys allow for higher compression ratios, reduced engine weight, and improved heat dissipation, contributing to increased engine efficiency and longevity.

Benefits of Advanced Materials in Rebuilding vs. Replacement

Engine builders must carefully consider the use of advanced materials in their projects:

- Rebuilding with Advanced Materials: Rebuilding an engine with advanced materials can enhance performance and fuel efficiency. However, it requires specialized knowledge, machining capabilities, and access to the latest materials, which may not be readily available to all engine builders.

- Replacement with Advanced Materials: Replacement engines, particularly remanufactured or new units, often come with advanced materials pre-integrated. This can be an attractive choice for those seeking the benefits of advanced materials without the complexities of sourcing and machining these materials themselves.

V. Performance Enhancements Through Technology

Direct Injection and Its Impact

Direct fuel injection technology has revolutionized engine efficiency and power delivery. By precisely injecting fuel directly into the combustion chamber, engines can achieve better fuel atomization, resulting in improved power output and fuel economy. Engine builders need to consider the compatibility of older engine blocks with direct injection systems when deciding between rebuilding and replacement.

Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, have become increasingly common in modern engines. These technologies significantly boost engine power by compressing air and increasing the amount of oxygen available for combustion. Engine builders exploring performance enhancements must decide whether to retrofit these systems into existing engines during rebuilding or opt for engines already equipped with them in the case of replacement.

Variable Valve Timing (VVT) and Efficiency Gains

Variable Valve Timing (VVT) technology allows engines to optimize valve timing based on driving conditions. This leads to improved efficiency at low RPMs and increased power at high RPMs. Engine builders need to evaluate whether incorporating VVT into a rebuilt engine is practical or if replacement engines with VVT capabilities are a more viable option.

VI. Electronics and Engine Management

Engine Control Units (ECUs)

Modern vehicles rely heavily on electronic control systems managed by Engine Control Units (ECUs). These computers govern various aspects of engine operation, including fuel injection, ignition timing, and emissions control. When rebuilding an engine, compatibility with the vehicle’s ECU is crucial. Engine builders must ensure that the rebuilt engine is equipped with the necessary sensors and components to interface effectively with the ECU.

Tuning and Calibration

The ability to tune and calibrate an engine for optimal performance has become more accessible thanks to technology. Aftermarket ECUs and tuning software allow for precise adjustments, enabling engine builders to fine-tune power delivery, fuel efficiency, and emissions control. This flexibility can be a significant advantage for those considering rebuilding.

Diagnostics and Troubleshooting

Modern vehicles also benefit from advanced diagnostics and troubleshooting capabilities. Onboard diagnostic systems (OBD-II) can pinpoint issues with engine performance quickly. When rebuilding, engine builders must have access to diagnostic tools and expertise to ensure the engine operates within specified parameters.

VII. Environmental Considerations

Emissions Compliance and Regulations

Emissions regulations have become increasingly stringent worldwide. Engine builders must consider whether rebuilding an older engine can meet current emissions standards. Replacement engines, especially new or remanufactured units, are often designed to comply with modern emissions requirements.

Eco-Friendly Options: Electric and Hybrid Engines

As the automotive industry embraces electric and hybrid technologies, engine builders may need to adapt their skills to work on these emerging powertrains. This shift raises questions about the future of traditional engine rebuilding and the need to diversify expertise.

VIII. Decision-Making Factors for Engine Builders

Cost Analysis: Rebuilding vs. Replacement

Balancing the budget is often a primary concern for both engine builders and vehicle owners. Engine rebuilding can be cost-effective, but it can also become expensive if the engine requires extensive machining and replacement of multiple components. On the other hand, replacement engines may have a higher upfront cost, but they often come with warranties and reduced labor expenses, potentially offering long-term cost savings.

Vehicle Application and Intended Use

The intended application and use of the vehicle play a crucial role in the decision-making process. For high-performance or specialized applications, engine builders may choose to rebuild, customizing the engine to meet specific requirements. For daily drivers or fleet vehicles, replacement engines may offer a more efficient and reliable solution.

Customer Preferences and Budget

Customer preferences are paramount. Some vehicle owners are passionate about preserving the original engine of a classic car, making rebuilding the ideal choice. Others prioritize reliability and warranty coverage, making replacement engines more appealing. Engine builders must communicate openly with customers to align their preferences and budget constraints with the most suitable option.

Long-Term Reliability and Warranty

Consideration of long-term reliability is crucial. Rebuilt engines can be tailored for durability and performance, but their longevity often depends on the skill of the builder and the quality of the components used. Replacement engines, particularly those with warranties, provide a sense of security regarding future performance and maintenance costs.

IX. Case Studies: Real-World Scenarios

Case Study 1: Restoring a Vintage Muscle Car

In this scenario, a dedicated enthusiast wants to restore a classic muscle car to its original glory. Rebuilding the original engine block becomes the preferred choice to maintain the car’s authenticity and value as a collector’s item.

Case Study 2: Fleet Maintenance and Cost Savings

A fleet manager responsible for a commercial vehicle fleet faces the challenge of reducing downtime and maintenance costs. Opting for replacement engines, such as remanufactured units, ensures consistent reliability and minimizes labor expenses over time.

Case Study 3: High-Performance Engine Upgrades

A performance shop aims to create a high-power racing engine for a customer’s project car. In this case, rebuilding the engine with advanced materials, forced induction, and precise tuning offers the flexibility to achieve the desired power and performance characteristics.

X. Future Trends in Engine Technology

Predictions and Innovations

The future of engine technology holds exciting possibilities. Predictions include further advancements in efficiency, improved hybrid powertrains, and increased use of artificial intelligence in engine management. Staying informed about these trends is essential for engine builders looking to remain at the forefront of their field.

The Intersection of AI and Engine Building

Artificial intelligence is making inroads into engine building, offering opportunities for predictive maintenance, real-time performance optimization, and automated quality control.

Embracing AI-driven tools can enhance efficiency and precision in the engine-building process.

Sustainable Engine Technologies

Environmental consciousness continues to drive innovation in engine technology. Sustainable solutions, such as hydrogen fuel cells and advanced electric powertrains, are shaping the future of transportation. Engine builders may need to adapt their skills to work on these emerging technologies.

XI. Conclusion: Navigating the Crossroads

In the ever-evolving landscape of engine technology, engine builders face a dynamic decision-making process when it comes to rebuilding or replacing engine blocks. While tradition and craftsmanship remain essential, embracing the latest technological advancements is equally vital.

By carefully evaluating factors such as cost, vehicle application, customer preferences, and long-term reliability, engine builders can make informed decisions that align with the needs of their projects and customers.

As we move into an era of sustainable technologies and artificial intelligence integration, the role of engine builders is set to evolve. Those who stay informed, adapt, and continue to master their craft will remain indispensable in the world of automotive engineering.

In the face of technological advancements, engine builders find themselves at a crossroads—yet, with knowledge and adaptability, they are poised to drive the future of automotive performance and reliability.

We have several Tips articles and videos on the subject of providing useful tips and tricks to address common problems to fix, and upgrades to improve your vehicle’s performance, reliability, and longevity.

Tips For Upgrading Your Vehicle

- What Are The Most Important Upgrades You Can Do To Your Car?

- Install a performance exhaust system

- Upgrade Your Air Filter

- Cold Air Intake System

- Spark plugs and wires

- Fuel System

- Change Your Oil Regularly

- Performance Chip

- Performance Tires

- Performance Camshaft

- Aftermarket Cylinder Heads

- Replace Your Brake Pads and Rotors

- Power Adders (Turbocharger or Supercharger)

- Nitrous Oxide System

- Rebuild or Replace your Engine Block