Advanced Materials in Automotive Design

1. Introduction

The relentless pursuit of efficiency and performance optimization in automotive engineering has perpetually driven the innovation and adaptation of new materials. Prominently, carbon fiber and titanium have emerged as pivotal elements due to their superior properties and transformative impacts on performance parts. These materials not only fulfill the requirements of strength and lightweight construction but also offer enhancements in fuel efficiency and emission reductions. This article delves into how carbon fiber and titanium are revolutionizing the design and operational efficiency of automotive components, setting new standards in the industry.

As we enter a new era of automotive design, the strategic integration of these materials is not just an option but a necessity for staying competitive in a market increasingly focused on sustainability and efficiency. This shift towards advanced materials is not merely a trend but a fundamental evolution in the fabric of automotive manufacturing that promises to redefine our expectations of performance and efficiency in high-end motorsports and consumer vehicles alike.

Moreover, the introduction of carbon fiber and titanium into the automotive industry serves as a beacon for further innovations in material science. By reducing the weight of vehicles, these materials contribute significantly to the overall efficiency, which is paramount in the era of electric vehicles where battery life and efficiency dictate market success. Understanding the properties and applications of these advanced materials is essential for any stakeholder in the automotive industry from engineers and designers to investors and policy-makers.

2. Historical Context and Evolution of Materials in Performance Parts

Initially, automotive manufacturers relied on traditional metals like steel and aluminum, which provided the necessary durability and were economically feasible. As technological advancements emerged, the automotive industry began exploring unconventional materials to surpass existing limitations of weight and mechanical properties. Carbon fiber and titanium entered the automotive scene in the late 20th century, quickly becoming synonymous with high-performance and aerospace applications. Their adoption marked a significant shift towards materials that could provide exceptional performance benefits, including reduced weight and increased resistance to environmental stressors, thus propelling the evolution of performance parts.

The transition to these advanced materials was fueled by the motorsports sector, where the marginal gains in performance can be the difference between winning and losing. Teams in Formula One and Le Mans series pioneered the use of carbon fiber and titanium, pushing the boundaries of what was technically possible and setting new benchmarks for the automotive industry at large. This spirit of innovation gradually permeated consumer markets, influencing the production of more accessible high-performance vehicles.

In response to the growing demand for better performance and efficiency, the research into and application of these materials have become more sophisticated. Today, the development of composite materials and advanced metal alloys is driven by computational modeling and high-tech manufacturing processes, enabling more precise and optimized use of materials in automotive parts.

3. Properties and Benefits of Carbon Fiber in Automotive Design

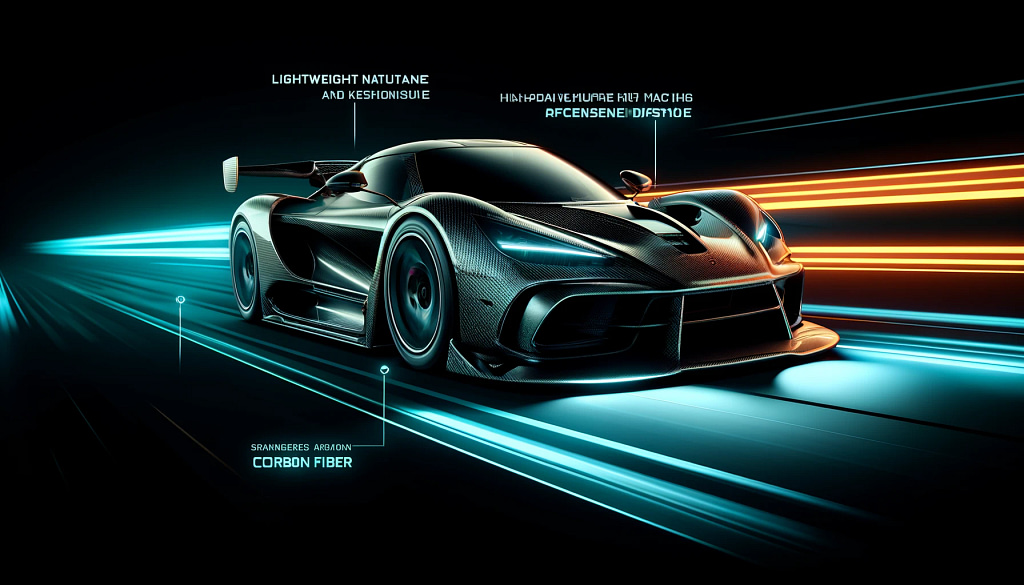

Carbon fiber is distinguished by its exceptional stiffness and strength-to-weight ratio, which are critical in automotive applications where every kilogram saved can significantly enhance vehicle dynamics and efficiency. Additionally, its superior fatigue resistance and ability to absorb energy in the event of a collision make it an ideal choice for safety-critical parts such as frames and body panels. Integrating carbon fiber in performance parts like spoilers, bumpers, and chassis, not only reduces the overall weight, but also maintains or enhances the structural integrity of the vehicle, thereby leading to improvements in speed, agility, and fuel economy.

The use of carbon fiber extends beyond mere weight reduction; its aesthetic qualities are highly valued in the luxury and sports car segments. The distinctive weave of carbon fiber parts can often be left exposed for visual appeal, adding to the vehicle’s market value and consumer desire. Furthermore, carbon fiber’s adaptability to complex shapes makes it ideal for innovative design philosophies that prioritize aerodynamic efficiency over traditional design constraints.

Moreover, the thermal properties of carbon fiber allow it to maintain its integrity under high temperatures, a crucial feature for components exposed to the intense heat of high-speed driving. This resistance to thermal expansion and contraction ensures that performance remains consistent in varying operational conditions, a key advantage in both racing circuits and regular road use.

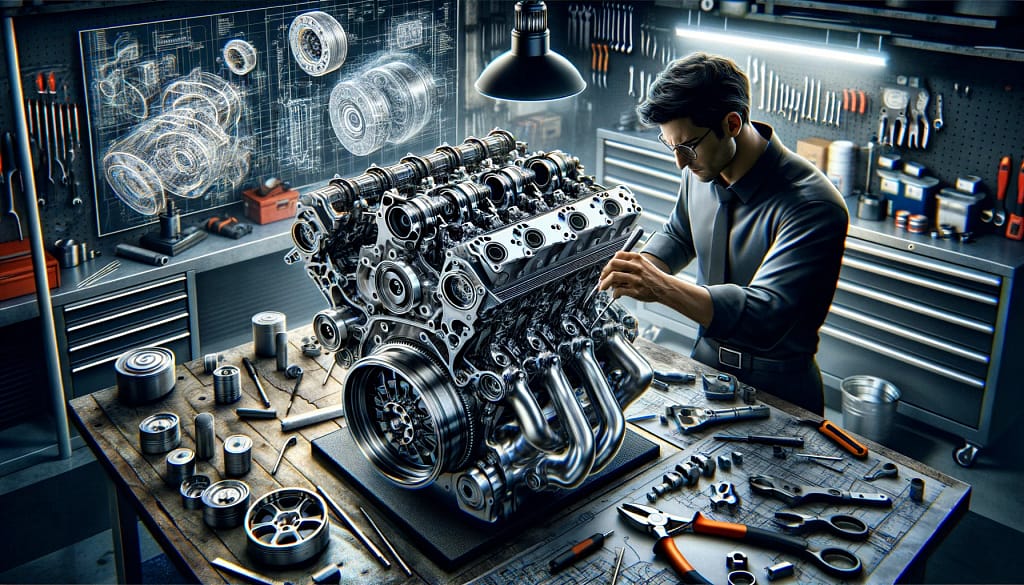

4. The Role of Titanium in Performance Automotive Engineering

Titanium’s high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand high temperatures make it invaluable in performance-critical automotive applications. Its use in engine components, such as connecting rods and exhaust systems, helps in reducing the overall mass and improving engine efficiency. Additionally, titanium’s non-magnetic and non-toxic properties make it environmentally favorable, which is increasingly important in the automotive industry’s shift towards sustainability. The metal’s unique characteristics enable the production of lighter, stronger, and more durable automotive parts that can endure the stresses of high-performance racing and everyday road use.

Titanium is not just used for its mechanical advantages; it also offers significant environmental benefits. As the automotive industry moves towards more sustainable practices, titanium’s lower environmental footprint becomes increasingly important. Its superior lifespan and recyclability, compared to traditional metals, make it a more sustainable choice, aligning with global environmental standards and consumer expectations for eco-friendly products.

The applications of titanium have expanded from purely structural to performance-enhancing features in automotive designs. Innovations in titanium alloy compositions have been pivotal in developing parts that are not only lighter but also capable of delivering greater power and stability. These advancements have opened new avenues for designing vehicles that offer both enhanced performance and efficiency without compromising on durability or safety.

5. Case Studies: Carbon Fiber and Titanium in Action

Formula One teams extensively utilize carbon fiber not only in their car’s chassis but also in integral components such as brake assemblies and wings to maximize strength and minimize weight. Similarly, titanium is prominently used in motorsports for critical engine and chassis components. For example, high-performance motorcycles and racing bikes employ titanium in their exhaust systems and frames to reduce weight and enhance structural rigidity. These practical implementations underscore the materials’ crucial roles in not only maintaining but significantly boosting the performance and safety standards of competitive automotive machinery.

The use of titanium and carbon fiber is not confined to elite motorsports. These materials are also integral to the aerospace industry, where their benefits translate into improvements in fuel economy and emissions reductions. For instance, Boeing and Airbus use carbon fiber composites extensively in the bodies and wings of their aircraft to achieve weight savings that contribute to more efficient flight profiles and reduced environmental impact. This cross-industry adoption underscores the versatility and high-value application of these materials.

Further expanding into consumer markets, carbon fiber, and titanium are now features of everyday vehicle enhancements, from carbon fiber-reinforced polymers in body panels to titanium fasteners in engine bays. These applications not only improve performance but also enhance the longevity and corrosion resistance of the parts, providing long-term value to consumers while pushing the envelope on what traditional materials can provide.

6. Comparative Analysis with Traditional Materials

Carbon fiber and titanium offer significant advantages over traditional materials like steel and aluminum, particularly in terms of strength, weight reduction, and durability. The lighter weight of these advanced materials contributes to better handling, reduced strain on other vehicle systems, and improved fuel efficiency. However, the high cost of carbon fiber and titanium is often justified in competitive sectors like racing and luxury car production, where their benefits can be fully leveraged. This section provides a detailed performance analysis comparing these materials across various dimensions, including mechanical properties, cost implications, and lifecycle impacts.

Despite their higher initial costs, the long-term benefits of carbon fiber and titanium can offset these expenses through increased durability and efficiency. These materials are particularly cost-effective in applications where performance and weight reduction are critical, such as in high-performance sports cars and aerospace applications. The lifecycle analysis of these materials often shows a lower total cost of ownership due to less frequent replacements and lower maintenance requirements.

The economic analysis of adopting these advanced materials also reflects broader industry trends toward sustainability and efficiency. As the cost of carbon fiber and titanium production decreases through advancements in technology and scaling of operations, these materials are becoming more accessible to a broader range of automotive applications, promising a future where high performance and sustainability go hand in hand.

7. Future Trends and Innovations in Material Science

The landscape of automotive materials is poised for radical changes with the introduction of hybrid composites and advanced metal alloys. Research into combining carbon fiber with metals like aluminum and titanium is expected to yield hybrid materials that could offer unprecedented performance characteristics. Moreover, the exploration of nanotechnology, particularly carbon nanotubes and graphene, promises to further enhance the properties of existing materials, potentially leading to lighter, stronger, and more efficient automotive components than ever before. These innovations highlight the dynamic nature of material science and its potential to redefine performance standards in the automotive industry.

The push towards greater sustainability is driving research in eco-friendly material alternatives that do not compromise on performance. Bio-based polymers and recycled composites are beginning to emerge as viable substitutes for traditional and advanced materials, offering a greener footprint while maintaining necessary mechanical properties. The development of these new materials is not just a testament to technological advancement but also a response to increasing environmental regulations and market demand for sustainable products.

In addition, the integration of smart materials, which can change properties based on environmental inputs, is setting the stage for the next revolution in automotive design. These materials could enable real-time adaptability of vehicle structures, optimizing performance based on changing driving conditions and potentially improving safety and efficiency. As material science continues to evolve, the possibility of integrating such advanced functionalities into everyday vehicles is becoming more tangible.

8. Conclusion

The integration of carbon fiber and titanium into automotive performance parts has not only enhanced current vehicle designs but also signaled a new era in material utilization that could significantly influence future automotive standards. As these materials continue to evolve, they will likely usher in new design paradigms that further optimize performance, efficiency, and sustainability in the automotive sector. While currently centered on high-performance and luxury markets, this evolution may soon trickle down to more broadly accessible vehicles, marking a significant milestone in automotive development.

As we look to the future, the ongoing advancements in material science will undoubtedly play a crucial role in shaping the automotive landscape. The exploration of new material combinations and the continuous improvement of carbon fiber and titanium production techniques will facilitate their broader adoption,

potentially transforming high-end motorsports and the entire spectrum of vehicle manufacturing. This progressive integration of advanced materials is not merely enhancing the performance and efficiency of vehicles but also redefining what is possible in automotive engineering.

More Articles On Performance Parts

- All Posts About Performance Parts

- Automotive Performance Enhancements: Unlocking The Potential

- The Evolution Of Safety Technologies In Motorsports: A Comprehensive Overview

- The Symphony Of Power: Navigating The World Of Performance Exhaust Systems

- Fueling Your Passion: The Essential Guide To Performance Parts

- Top 10 Performance Exhaust Systems For Speed Enthusiasts

- What Are The Most Important Upgrades You Can Do To Your Car?