An Overview for Beginners

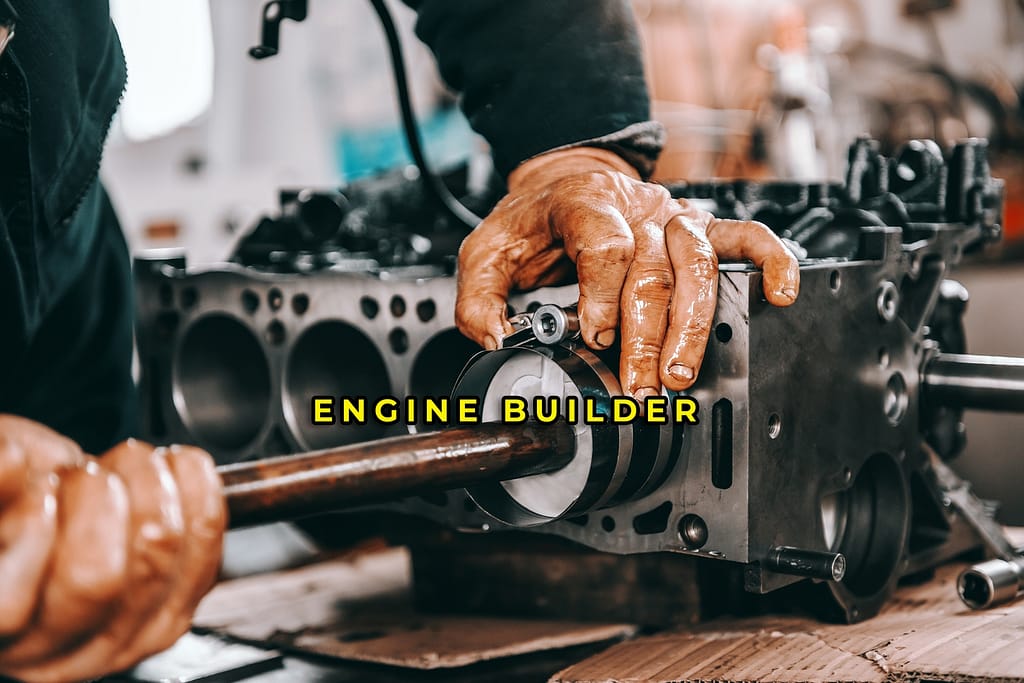

Building your very own racecar engine may not be the quickest way to get your automobile prepared for the track. But, doing your own engine build can be the most fulfilling!

High-horsepower crate engines from the Big 3 car manufactures as well as full-bore race engines from the builders like Reher & Morrison, Scott Shafiroff, Steve Schmidt, as well as plenty of others, have actually tempted many racers to just buy an engine, instead of building one themselves. What’s less complex than buying and setting up your engine, and just go racing.

Should I Build It?

Nevertheless, not every person can afford to spend thousands of dollars outright on a pre-built racing engine.

Many resourceful and cost conscious racers still build their very own engines, commonly working inline with a reputable machine shop. Most of these racers have been building their very own engines since they began racing. Also they can be equally as competitive as the racers with the store-bought engines.

Get the Right Parts for the engine build

Picking the parts and constructing a race engine might seem challenging and also frustrating in the beginning. The whole process can be really satisfying. We recommend getting in touch with a reliable racer friend who has engine-building experience. And then they can help you get started as well as keep you going in the best direction. Building engines includes a substantial learning curve. No price can be put on the pride as well as experience acquired. Do not hesitate to ask questions.

hesitate to ask questions.

Even the most skilled engine builders are known to consult with manufacturers’ tech workers to help with the parts selection. A lot of aftermarket businesses have tech phone numbers for this reason. These individuals are always more than happy to help, especially if you’re aiming to purchase their part. Make certain these tech people understand where and what you intend to race. Also exactly how fast and quick you intend to go, and then follow their recommendations.

Picking a Machine Shop

Here is a crucial requirement for developing any type of competitive and affordable race engine. Pick a good, and trusted machine shop. Widely known shops that specialize in racing engines are generally a good place to start. Do not hesitate to drive a good distance to a prospective shop if there aren’t any local ones available. Remember, as well, that shops specializing in stock rebuilds generally don’t have the most modern-day equipment. They also don’t pay the salaries needed to retain the best machinists. At the end of the day, you get what you pay for.

Make sure the machinist recognizes exactly what it is you want and expect from this engine. And also, don’t just drop off an engine in March, when shops are their busiest. And then expect it to be ready on the first of April.

Initially, the machinist begins work on your engine. The normal process begins with hot tanking the block to cleanse it extensively. Magnafluxing is thoroughly recommended to look for cracks. Boring, decking, honing, and installation of new cam bearings and freeze plugs all take place next.

While the engine is at the machine shop, do some research and also assess the assembly process. A pair of reference books worth reading, Engine Blueprinting: Practical Methods for Racing and Rebuilding (S-A Design) by Rick Voegelin. Another is Power Keys by Smokey Yunick can be outstanding research study guides. Both publications cover all stages of engine building. It goes from the necessary fundamentals to the steps made use of by seasoned engine builders.

Engine Blueprinting

In the book Engine Blueprinting, it also includes log sheets in the back that can be quickly copied. The log sheets can also be made use of to record every element of the engine’s assembly procedure. Detailed, accurate record-keeping that tracks component choice, specifications as well as tolerances for an engine. As well as any carried out machining processes will certainly generate useful reference material for future engine building efforts.

When you get your engine back

The engine comes back from the shop, Now the setting up process will go far more smoothly if you can collect a number of specialized tools. We suggest a strong engine stand, a quality torque wrench, deck plate, piston ring installation device, and piston ring filer. Also a set of micrometers to determine the crankshaft journals and also pistons. A dial bore gauge for measuring cylinder bores as well as bearing clearances. Also a dial indicator with a magnetic stand for degreeing camshafts, checking deck heights, and so on. And also most notably, a neat, tidy work area.

Check the job they did at the shop by examining main and rod journal sizing, especially if the crank was ground. Also confirm piston-to-wall clearances is always an excellent suggestion prior to final clean-up and also assembly. Become familiar with utilizing the above-mentioned tools as well as really feel comfortable that you are getting precise readings. You will promptly see the quality of the machine work you’re obtaining.

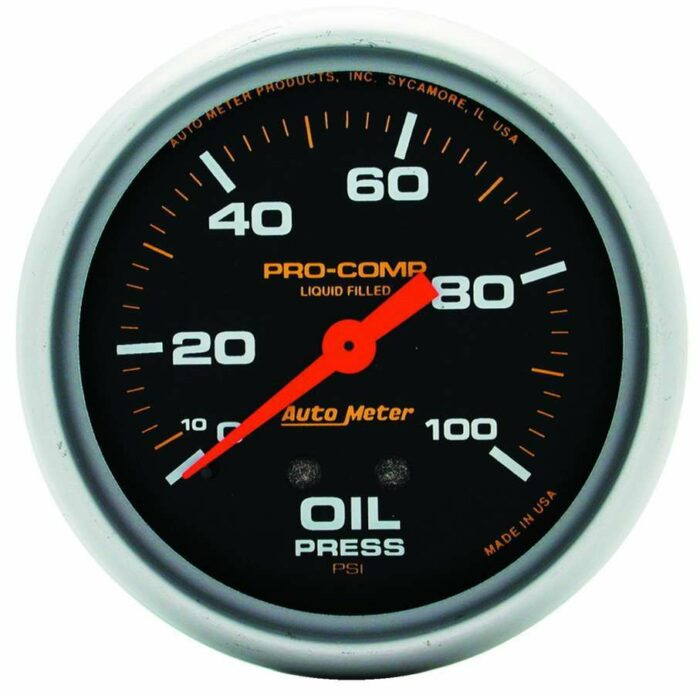

Mount and torque down the deck plate (readily available from business such as BHJ). This is to imitate the stress and anxieties of a bolted-on cylinder head. Also to inspect not just the piston-to-wall clearance, but also how straight and true the cylinder wall surfaces are. Cylinder walls .002 ″–.003 ″ or more out-of-round or that are tapered might be acceptable for the Uber driver. But this will never supply reliable piston ring sealing in a race engine.

Block Evaluation

Evaluating the block after machining for a race engine. Building a race engine requires patience and attention to detail, but can be an extremely gratifying experience.

Don’t let reasonably straightforward chores intimidate you like file-fitting piston rings or degreeing the camshaft. Sure, they did not perform it on the production line. Yet they are examples of the difference between basic engine building and true engine “blueprinting”.

You need to take your time as well as exercise patience. When you do everything correctly, you’ll understand. The suitable time to build a race engine is during the off-season when things are not so frantic. Don’t attempt have machine work done during spring and summer, because that’s when the shops are the busiest. Then afterwards attempting to quickly assemble an engine in the middle of the auto racing season.

This post was inspired by an article written By Jim Kaekel, Jr, on Motorstate’s site. Here is a post on how to Maintain Your Race Engine