The Great American Valvetrain Co.

Rockers

What do you look for when setting roller geometry and sweep pattern?

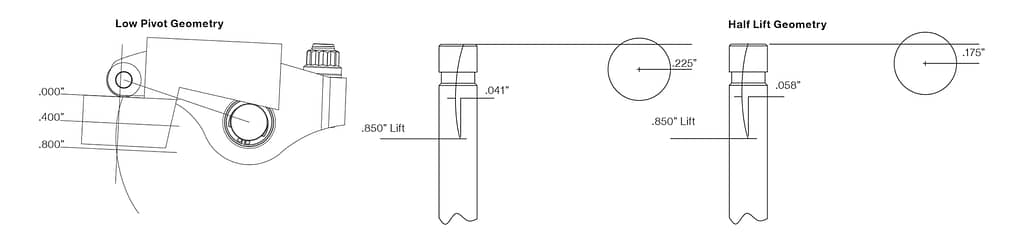

We set our aluminum systems with a low pivot geometry which results in the majority of the sweep pattern occurring while spring pressures are at their lower range. The majority of roller travel occurs from zero lash to half lift which results in minimum roller travel for the duration of lift when spring pressures are greatest. At zero lash, the roller should start approximately .050” behind the center of the valve stem, sweep across center and end near the center at full lift.

What is the proper way to set valve lash?

Starting at #1 cylinder, rotate the engine until the #1 exhaust rocker just starts to open the exhaust valve. Set the valve lash on #1 intake rocker at this time. Continue rotating the assembly and stop when #1 intake rocker starts returning from full lift. The lash on #1 exhaust can now be set. Continue this procedure for the remaining cylinders following the engines firing order.

Do I have to torque the adjuster nuts?

We highly recommend using a torque wrench when setting valve lash. Our recommended torque setting for a typical 3/8-24 cup or ball style adjuster is 25 lbs/ft. Over tightening the adjuster nut stresses the thread area in the rocker body leading to premature rocker arm failure.

Are there any break-in procedures I need to follow?

The most critical step in initial start-up is the proper break-in of the adjuster cup to pushrod tip surfaces. We supply a high pressure lube with all rocker kits to prevent premature failure and wear of the adjuster cup area. The shaft bearings are fully lubricated from Jesel and only require splash lubrication once running.

My adjuster is screwed fully into the body and I still can’t get lash. Can I drill out the body and sink the adjuster?

NO! We see more rocker failures due to this procedure. Invest in shorter pushrods or if it’s an emergency, raise the stand slightly. NEVER modify the adjuster cup counter-bore area.

How far out can I run my adjuster?

We recommend not running the adjuster turned out more than two revolutions from the fully seated position. All rockers are shipped from Jesel with the adjuster set at one full turn from seated. Operating an engine with the adjusters more than two turns out puts excessive loads on the cup area and may lead to premature failure of the adjuster.

When should I be running needle bearing nose rollers?

We highly recommend needle nose rollers on any application using 5/16” diameter or smaller valve stems. Open spring pressures and valve lifts are also factors to look at when ordering a rocker system. We have what we call our 800-800 rule. Any application running more than 800 lbs open or over .800” worth of total valve lift should be running needle nose rollers.

My rockers are rubbing the retainers. Can I relieve the area for extra clearance?

Yes, it is safe to remove a small amount of material from the underside of the rocker to gain additional clearance between the body and retainer. We recommend using a ball type end mill and not something like a “fly-cutter” which will leave sharp edges. Stress fractures can occur if sharp edges are left after machining so be sure to round all sharp edges. We can provide this option when rockers are being manufactured.

When should I replace my rocker arms?

There is no set time to replace a rocker arm body and generally there are many factors involved such as spring pressures, operating temperatures and the occasional over-rev. Aluminum bodied rockers will fatigue over time and varies by application and operating environments. One of the first signs of fatigue is the failure of the body surrounding the adjuster.

Shaft Rocker Arm Geometry

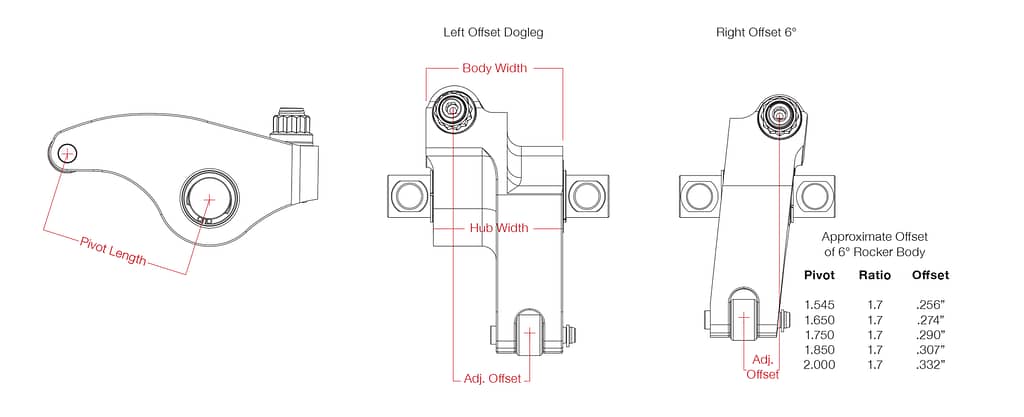

Rocker geometry is a function of the arc generated from the rocker arm and the relationship of the valve tip to rocker shaft height. Using this arc correctly is the difference between a smooth operating valvetrain and a valvetrain of worn out parts. Jesel’s Low Pivot geometry utilizes the portion of the arc that produces a minimal sweep pattern from half to full lift, a point at which spring pressures are exponentially increasing. These added spring forces transferred against the nose roller have the potential to cause the roller to skid instead of roll across the tip bending the valve stem and wearing the guides. By minimizing the roller travel distance under high spring loads, the potential of roller skidding is reduced and valve guide wear is decreased tremendously. As illustrated below, the Jesel Low Pivot geometry yielded almost .020” less roller travel during the critical stages of lift compared to a rocker set up for a symmetrical half-lift geometry.

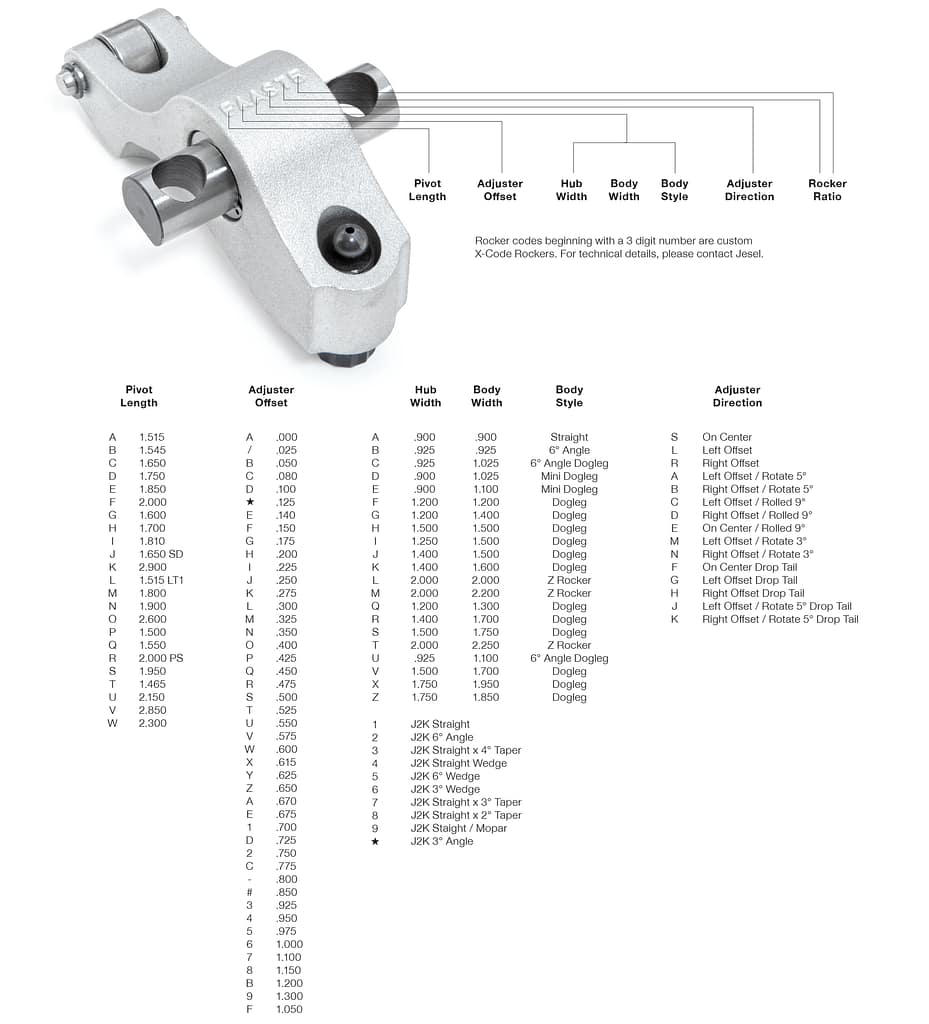

Shaft Rocker Arm Code Chart

If you are interested in any of the Jesel product line, we here at Uzbasic Motorsports are an approved Dealership for Jesel Sportsman, Pro, and Nitro/Alcohol Series Rockers and Lifters, as well as Belt Drives and Cam Cores. Contact Us and we will get you taken care of. Just let us know what you need.

Here is an article that you might find interesting on Camshaft Degreeing. Also, take a look at Bad Evap Canister.

If you’re a fan of Jesel products, then go take a look at some of these other articles.

Jesel Valvetrain – Lifters FAQ’s

Article and images provided by Jesel Drivetrain Innovations.